Nuclear in your backyard? Tiny reactors could one day power towns and campuses – but community input

Small-scale nuclear reactors are a promising power source. But implementing them will require overcoming technical and societal challenges.

You might imagine nuclear power plants as behemoth facilities spanning hundreds of acres. Nuclear microreactors, by contrast, could sit on land the size of a football field and power a whole town.

However, after decades of fraught relationships between the nuclear industry and communities in many parts of the U.S., building these tiny reactors requires reckoning with the complex history of nuclear technology and rebuilding public trust.

Microreactor technology for use in towns or cities hasn’t been developed yet, but many researchers have been building the case for its use.

For example, this technology could benefit college campuses, remote communities in Alaska primarily powered by oil and diesel, tech companies looking for reliable electricity for AI data centers, companies in need of high-temperature heat for manufacturing and industrial processes, mining operations that need a clean energy source and even military bases in search of a secure source of energy.

I’m a nuclear engineer who has been exploring nuclear microreactors’ potential. My research and teaching focuses on some of the questions that would come with placing miniature nuclear reactors close to where people live.

Microreactors: A history

Nuclear microreactors as a technology are both new and old. In the 1940s and ’50s, the American military and government began developing small reactors and nuclear batteries to power submarines and spacecraft.

After developing these small-scale reactors and batteries for various missions, the nuclear industry’s focus shifted to power reactors. They began to rapidly scale up their designs from producing tens of megawatts to the gigawatt-scale systems common around the world today.

These historical reactors were small because scientists were still learning about the physics and engineering underlying these systems. Today, engineers are deliberately designing microreactors to be small.

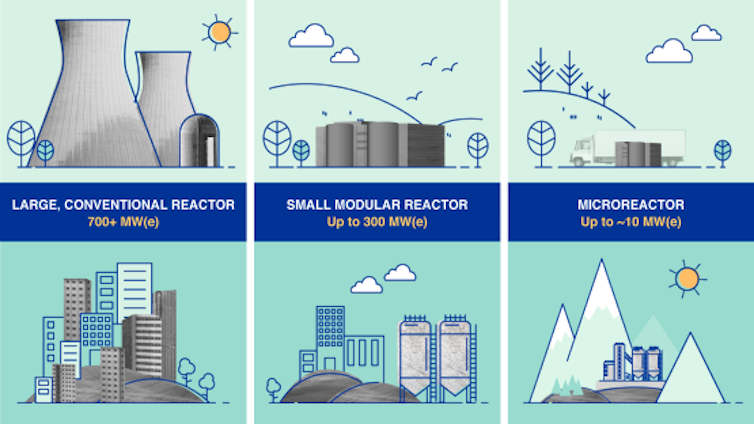

Microreactors aren’t to be confused with small modular reactors – these are often scaled-down, modularized versions of large reactors. Small, modular reactors can be built as single units or in clusters to achieve the same capacity as a full-size reactor. Microreactors would be smaller than these, with a power capacity under 20 megawatts.

Manufacturing and cost

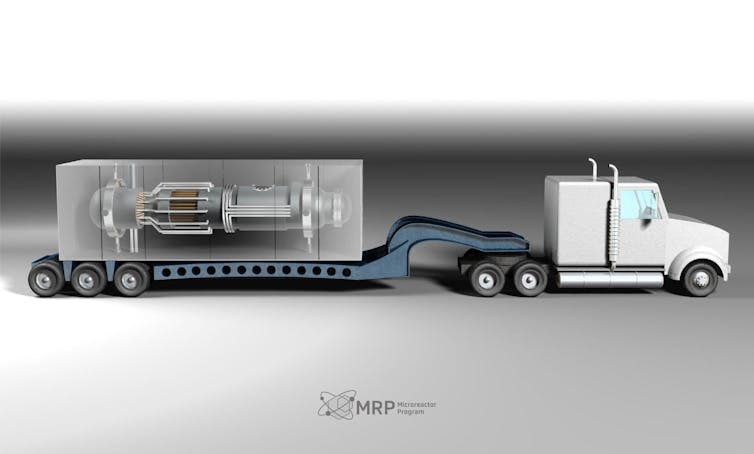

Because they’re small, microreactors wouldn’t require a massive, multiyear construction project like large nuclear power reactors. Several units could be assembled in a factory each year and shipped off to their final destinations in a truck or on a barge.

Large reactors are not inherently flawed – in many ways, they remain the more economic nuclear energy option. However, electric utility companies have recently hesitated to invest in large reactors because of the multibillion-dollar nature of these projects.

Microreactors require a different but equally significant kind of investment. Though individual units will have a significantly lower price tag, building a factory to produce these microreactors is a massive undertaking. Reactor companies are waiting for their order books to fill up before investing in factories.

It’s a catch-22. Without orders, technology developers are unlikely to build microreactor factories. And future users of these new reactors are unlikely to place orders until this new style of production has been tested and the initial units built.

Future users are also waiting to see what the microreactors will actually cost. Reactor developers have put forward many cost estimates, but in the past, estimates for nuclear reactors haven’t always been reliable. Developers likely won’t know the true numbers until the reactors are actually built.

Initial “first of a kind” units will undoubtedly cost significantly more than later units. As manufacturers learn the best production processes, they’ll be able to make more reactors for less.

In this paradoxical situation in which developers are waiting for orders and users are waiting to see the economics of initial reactors, government funding for building demonstration projects could help usher microreactor technology from early designs to the market.

First movers such as national laboratories, universities, data centers and military bases that are willing to buy these initial reactors also have a role to play in validating the economic feasibility of these new reactors.

Today’s microreactors

In a nuclear reactor, the combination of nuclear fuel and coolant – which is the substance used to both cool the fuel and transport the heat generated by it – used in its design determines what situations it will work best in. Many nonwater coolants can allow reactors to operate at lower pressures, which is a little more safe.

The microreactors being developed today are based on a wide range of reactor technologies and make use of many different combinations of nuclear fuels and coolants.

Some reactors, such as the submarine propulsion reactors, are small, pressurized water reactors – the same basic technology used in most large-scale nuclear power plants. Others use configurations that resemble the small reactors in spacecraft. Still others make use of nuclear fuel and coolant combinations previously attempted in much larger reactors, such as high-temperature gas reactors, sodium fast reactors and even molten salt reactors.

Though encompassing a range of technologies, microreactors are all significantly simpler than the large reactors in use today. In many cases, they have few to no moving parts.

Microreactors, by virtue of being significantly simpler, are going to be more knowable. Because they’re easier to study and understand, simpler reactor systems have fewer points of failure and safety concerns.

Complex systems, such as the large nuclear power reactors, can be fundamentally unknowable, with unexpected entanglements of “unknown unknowns” creating instabilities, safety concerns and potential for failure. Large reactors operate safely today because we have learned about these unknown unknowns over decades of operation. Microreactors, because of their simplicity, will fundamentally be safer and more predictable than the large reactors were when they were first built.

Siting microreactors

Although the Department of Energy oversees microreactor demonstration projects, commercial deployment of microreactors requires approval from the U.S. Nuclear Regulatory Commission, which could take several years and may ultimately determine how soon commercial reactors can be built. Several designs are now approaching or in the early stages of review.

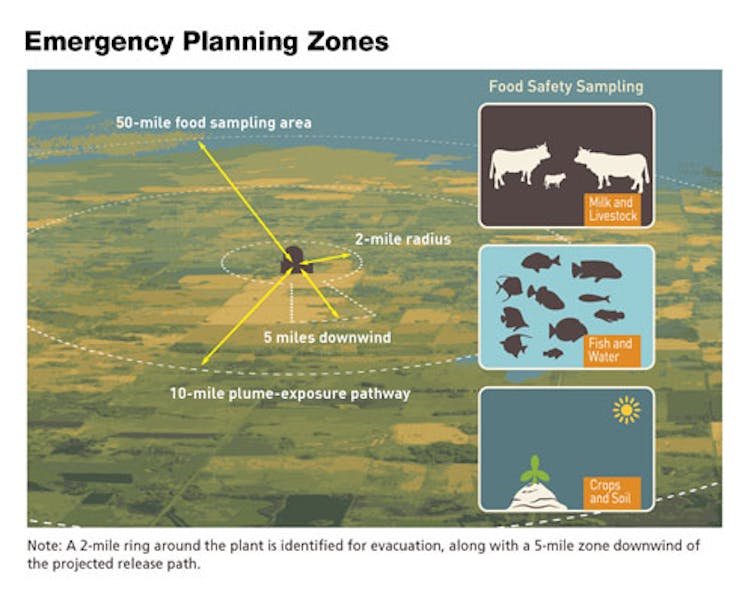

To keep people safe, large reactors have designated emergency planning zones – usually 10 and 50 miles around – which require different degrees of planning and protection to enter. The 10-mile zone has specific shelters and evacuation plans in place, while people in the 50-mile zone may need to take precautions about what they eat and drink in the event of a catastrophic accident but will not need to evacuate.

Because microreactors are smaller and simpler, developers and regulators may significantly reduce their emergency planning zones. The zones could extend only to the facility’s site boundary, or perhaps a few hundred meters beyond it.

A reduced emergency planning zone could mean that microreactors could be built in towns and cities, or embedded in remote communities. They might one day become as ubiquitous as the solar panels and windmills you see when driving through the countryside. And like the submarine reactors that can power a small underwater community of 100, one microreactor could power a rural town.

But even if siting a nuclear microreactor near a town is technically feasible, would the community accept it?

Public engagement

My lab’s ongoing research suggests that the answer to this question is contingent on how technology developers engage with the communities that may host a microreactor. If they attempt to unilaterally decide, announce and defend their decision to build a microreactor without input, communities will likely push back.

However, if developers work with communities to understand their hopes, concerns and priorities, they will likely find that many people are receptive to hyperlocal nuclear energy facilities.

My team’s initial findings suggest that there isn’t a one-size-fits-all approach for designing these facilities. Each community will have its own set of preferences that developers will need to navigate alongside the engineering questions.

In our discussions with community members in southeast Michigan, my research team has seen interest in designing these small energy facilities as a feature of the community that’s easily accessible to local residents. Community members designing hypothetical microreactor facilities with us have proposed shared spaces, recreational facilities, onsite visitor centers or science museums, and public art projects. Instead of hiding these facilities out of sight, they want these places to be inviting and beautiful.

Aditi Verma receives research funding from the U.S. Department of Energy. She is a board member for the Good Energy Collective and serves on various expert working groups of the OECD Nuclear Energy Agency.

Read These Next

Cuba’s speedboat shootout recalls long history of exile groups engaged in covert ops aimed at regime

From the 1960s onward, dissident Cubans in exile have sought to undermine the government in Havana −…

Nanoparticles and artificial intelligence can help researchers detect pollutants in water, soil and

Tiny particles bounce light around in a unique way, a property that researchers are using to detect…

Tiny recording backpacks reveal bats’ surprising hunting strategy

By listening in on their nightly hunts, scientists discovered that small, fringe-lipped bats are unexpectedly…