Where does your glass come from?

Glass seems simple − it’s just sand and a few more ingredients. Yet mining and production are rarely local, raising questions about sustainability.

The word “local” has become synonymous with sustainability, whether it’s food, clothes or the materials used to construct buildings. But while consumers can probably go to a local lumberyard to buy lumber from sustainably grown trees cut at nearby sawmills, no one asks for local glass.

If they did, it would be hard to give an answer.

The raw materials that go into glass – silica sand, soda ash and limestone – are natural, but the sources of those materials are rarely known to the buyer.

The process by which sand becomes sheets of glass is often far from transparent. The sand, which makes up over 70% of glass, could come from a faraway riverbed, lakeshore or inland limestone outcrop. Sand with at least 95% silica content is called silica sand, and only the purest is suitable for architectural glass production. Such sand is found in limited areas.

If the glass is colorless, its potential sources are even more limited, because colorless low-iron glass – popularized by Apple’s flagship stores and luxury towers around the world – requires 99% pure silica sand.

Glass production in Venice

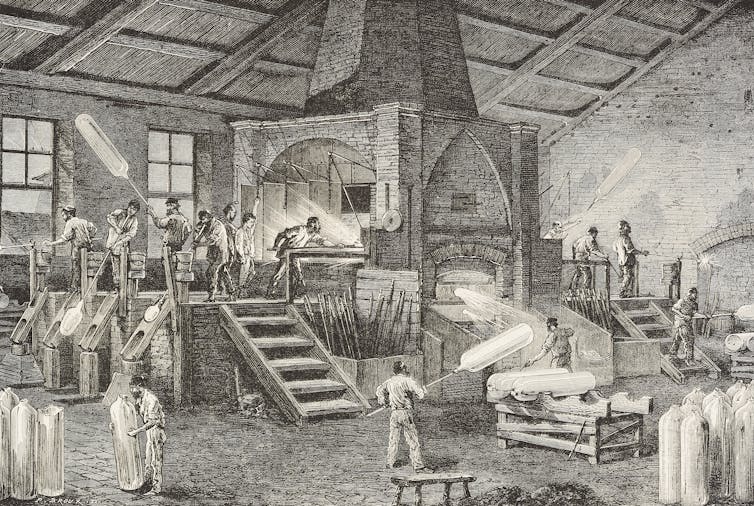

The mysteries of glass production have historic precedent that can be traced back to trade secrets of the Venetian Empire.

Venice, particularly the island of Murano, became the center for glass production largely due to its strategic location for importing raw materials and production know-how and exporting coveted glass objects.

From the 11th to the 16th centuries, the secrets of glassmaking were protected by the Venetians until three glassmakers were smuggled out by King Louis XIV of France, who applied the technology to create the Palace of Versailles’ Hall of Mirrors.

Venice was an otherwise unlikely location for glassmaking.

Neither the primary materials of sand and soda ash (sodium carbonate) nor the firewood for the medieval Venetian glassmakers were found in the city’s immediate vicinity. They were transported from the riverbeds of the Ticino River in Switzerland and the Agide River, which flows from the Austria-Switzerland border to the Adriatic Sea south of Venice. Soda ash, which is needed to lower the melting point of silica sand, was brought from Syria and Egypt.

So Venetian glass production was not local; it was dependent on precious resources imported from afar on ships.

Rising demand for low-iron, seamless glass

In the past few decades, low-iron glass, known for its colorlessness, has become the contemporary symbol of high-end architecture. The glass appears to disappear.

Low-iron glass is made from ultrapure sand that is low in iron oxide. Iron causes the green tint seen in ordinary glass. In architecture, low-iron glass doesn’t affect the performance – only the appearance. But it is prized.

In the U.S., this type of sand is found in a few locations, primarily in Minnesota, Wisconsin, Illinois and Missouri, where sand as white and fine as sugar – thus called saccharoidal – is mined from St. Peter sandstone. Other locations where it can be found around the world include Queensland in Australia and parts of China. Less pure sand can be purified by methods such as acid washing or magnetic separation.

Perhaps no corporation has popularized low-iron and seamless glass in architecture more than the technology giant Apple.

Glass has become fundamentally linked with Apple’s products and architecture, including its flagship stores’ expensive and daring experiments in architectural uses of glass.

Apple’s first showroom, completed in Soho in New York in 2002, showcased all-glass stairs that were strengthened with hurricane- and bullet-resistant plastic interlayers sandwiched between five sheets of glass. The treads attach to all glass walls with a hockey puck-size titanium hardware, making both the glass stairs and the shoppers appear to float.

The company’s iconic flagship store near New York’s Central Park is an all-glass cube measuring 32½ feet (10 meters) on each side and serving as a vestibule to the store below. The first version was completed in 2006 using 90 panels, which was a technical feat. Then, in 2011, Apple reconstructed the cube in the same location, same size, but with only 15 panels, minimizing the number of seams and hardware while maximizing transparency.

Today, low-iron glass has become the standard for high-profile architecture and those who can afford it, including the “pencil towers” in Manhattan’s Billionaires’ Row.

Glass’s climate impact

Glass walls common in high-rise buildings today have other drawbacks. They help to heat up the room during increasingly hot summers and contribute to heat loss in winter, increasing dependence on artificial cooling and heating.

The glassmaking process is energy intensive and relies on nonrenewable resources.

To bring sand to its molten state, the furnace must be heated to over 2,700 degrees Fahrenheit (1,500 degrees Celisus) for as long as 50 hours, which requires burning fossil fuels such as natural gas, releasing greenhouse gases. Once heated to that temperature, the furnace runs 24/7 and is rarely shut down.

The soda ash and limestone also release carbon dioxide during melting. Moreover, glass production requires mining or producing nonrenewable natural resources such as sand, soda ash, lime and fuel. Transporting them further increases emissions.

Production and fabrication of extra-large glass panels rely on specialized equipment and occur only at a limited number of plants in the world, meaning transportation increases the carbon footprint.

Architectural glass is also difficult to recycle, largely due to the labor involved in separating glass from the building assembly.

Although glass is touted as infinitely recyclable, only 6% of architectural glass is downcycled into glass products that require less purity and precision, and almost none is recycled into architectural glass. The rest ends up in landfills.

The increasing demand for glass that is colorless, extra large and seamless contributes to glass’s sustainability problem.

How can we make glass more sustainable?

There are ways to reduce glass’s environmental footprint.

Researchers and companies are working on new types of glass that could lower its climate impact, such as using materials that lower the amount of heat necessary to make glass. Replacing natural gas, typically used in glassmaking, with less-polluting power sources can also reduce emissions.

Low-e coatings, a thin coat of silver sprayed onto a glass surface, can help reduce the amount of heat that reaches a building’s interior by reflecting both the visible light and heat, but the coating can’t fully eliminate solar heat gain.

People can also alter their standards and accept smaller and less ultraclear panels. Think of the green tint not as impure but natural.

Aki Ishida does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

Read These Next

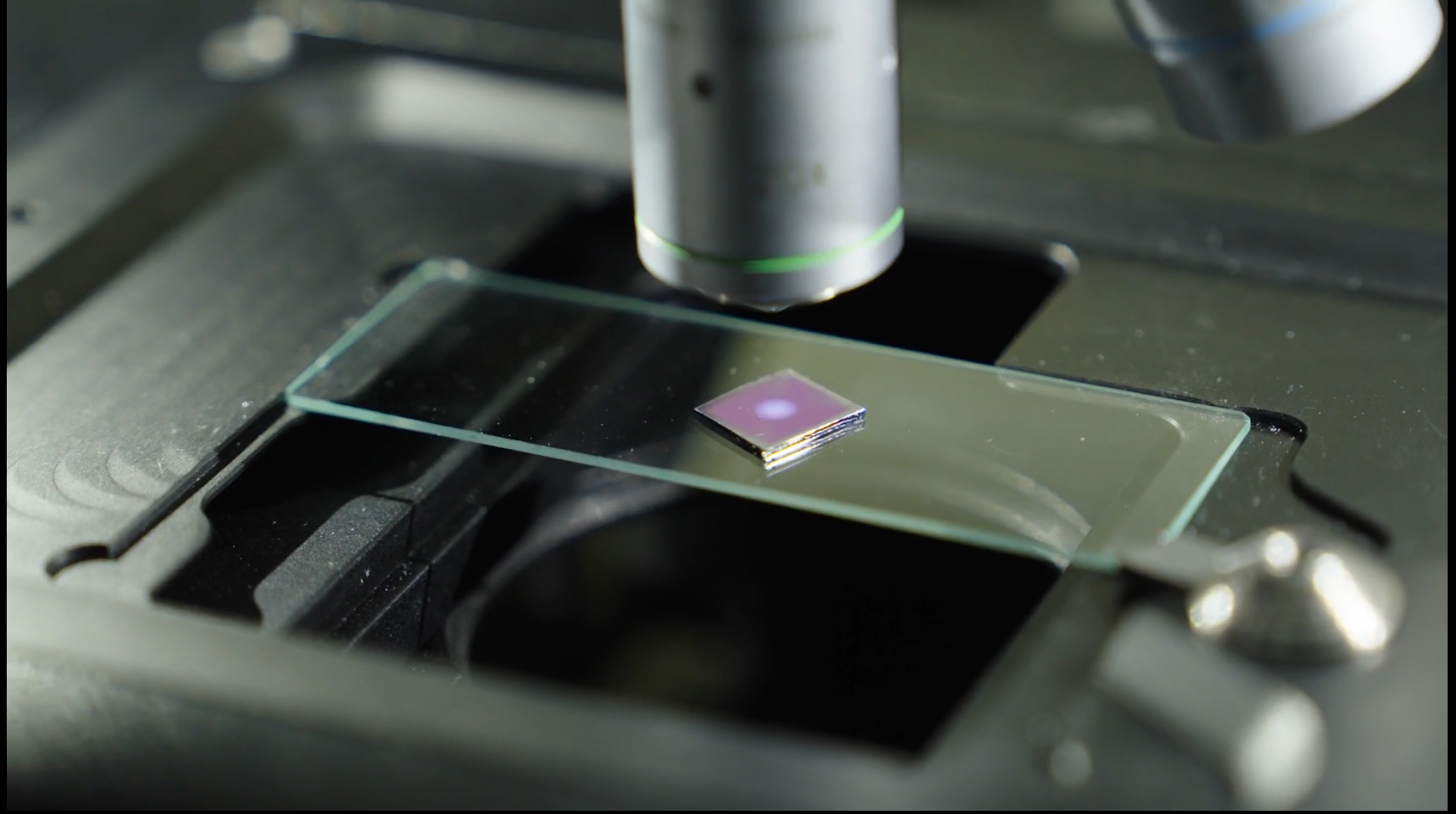

Nanoparticles and artificial intelligence can help researchers detect pollutants in water, soil and

Tiny particles bounce light around in a unique way, a property that researchers are using to detect…

Picky eating starts in the womb – a nutritional neuroscientist explains how to expand your child’s p

While genes do influence some food preferences, positive experiences can help make new tastes easier…

How transparent policies can protect Florida school libraries amid efforts to ban books

Well-designed school library policies make space for community feedback while preserving intellectual…