3D-printed model of a 500-year-old prosthetic hand hints at life of a Renaissance amputee

When historians and engineers work together, they can bring a version of the past back to life.

To think about an artificial limb is to think about a person. It’s an object of touch and motion made to be used, one that attaches to the body and interacts with its user’s world.

Historical artifacts of prosthetic limbs are far removed from this lived context. Their users are gone. They are damaged – deteriorated by time and exposure to the elements. They are motionless, kept on display or in museum storage.

Yet, such artifacts are rare direct sources into the lives of historical amputees. We focus on the tools amputees used in 16th- and 17th-century Europe. There are few records written from amputees’ perspectives at that time, and those that exist say little about what everyday life with a prosthesis was like.

Engineering offers historians new tools to examine physical evidence. This is particularly important for the study of early modern mechanical hands, a new kind of prosthetic technology that appeared at the turn of the 16th century. Most of the artifacts are of unknown provenance. Many work only partially and some not at all. Their practical functions remain a mystery.

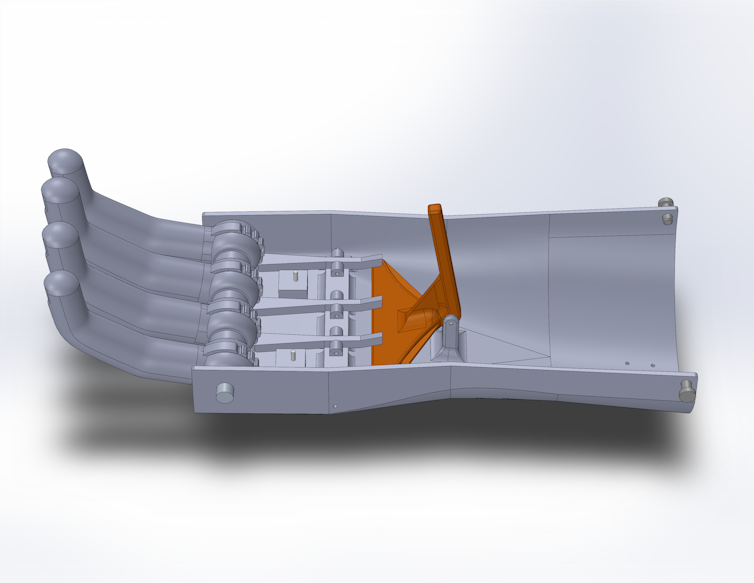

But computer-aided design software can help scholars reconstruct the artifacts’ internal mechanisms. This, in turn, helps us understand how the objects once moved.

Even more exciting, 3D printing lets scholars create physical models. Rather than imagining how a Renaissance prosthesis worked, scholars can physically test one. It’s a form of investigation that opens new possibilities for exploring the development of prosthetic technology and user experience through the centuries. It creates a trail of breadcrumbs that can bring us closer to the everyday experiences of premodern amputees.

But what does this work, which brings together two very different fields, look like in action?

What follows is a glimpse into our experience of collaboration on a team of historians and engineers, told through the story of one week. Working together, we shared a model of a 16th-century prosthesis with the public and learned a lesson about humans and technology in the process.

A historian encounters a broken model

THE HISTORIAN: On a cloudy day in late March, I walked into the University of Alabama Birmingham’s Center for Teaching and Learning holding a weatherproof case and brimming with excitement. Nestled within the case’s foam inserts was a functioning 3D-printed model of a 500-year-old prosthetic hand.

Fifteen minutes later, it broke.

For two years, my team of historians and engineers at Auburn University had worked tirelessly to turn an idea – recreating the mechanisms of a 16th-century artifact from Germany – into reality. The original iron prosthesis, the Kassel Hand, is one of approximately 35 from Renaissance Europe known today.

As an early modern historian who studies these artifacts, I work with a mechanical engineer, Chad Rose, to find new ways to explore them. The Kassel Hand is our case study. Our goal is to learn more about the life of the unknown person who used this artifact 500 years ago.

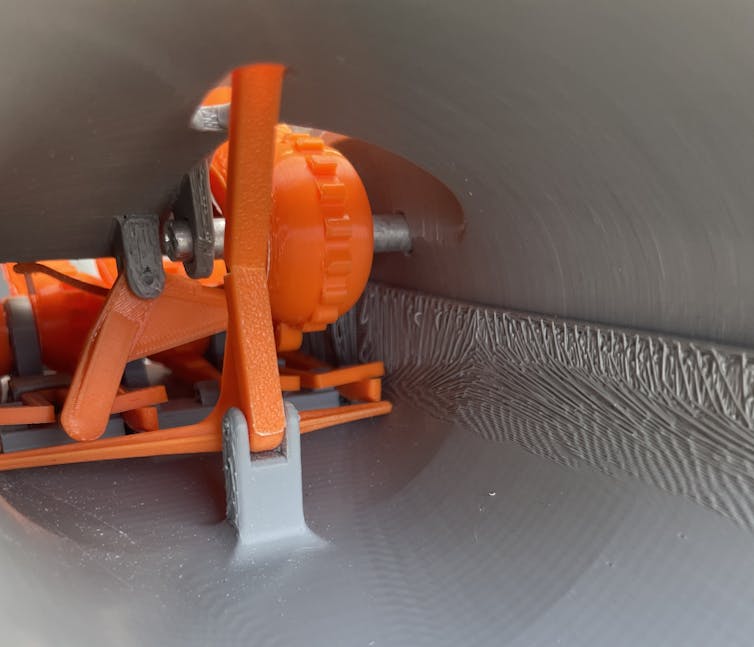

Using 3D-printed models, we’ve run experiments to test what kinds of activities its user could have performed with it. We modeled in inexpensive polylactic acid – plastic – to make this fragile artifact accessible to anyone with a consumer-grade 3D printer. But before sharing our files with the public, we needed to see how the model fared when others handled it.

An invitation to guest lecture on our experiments in Birmingham was our opportunity to do just that.

We brought two models. The main release lever broke first in one and then the other. This lever has an interior triangular plate connected to a thin rod that juts out of the wrist like a trigger. After pressing the fingers into a locked position, pulling the trigger is the only way to free them. If it breaks, the fingers become stuck.

I was baffled. During testing, the model had lifted a 20-pound simulation of a chest lid by its fingertips. Yet, the first time we shared it with a general audience, a mechanism that had never broken in testing simply snapped.

Was it a printing error? Material defect? Design flaw?

We consulted our Hand Whisperer: our lead student engineer whose feel for how the model works appears at times preternatural.

An engineer becomes a hand whisperer

THE ENGINEER: I was sitting at my desk in Auburn’s mechanical engineering 3D print lab when I heard the news.

As a mechanical engineering graduate student concentrating on additive manufacturing, commonly known as 3D printing, I explore how to use this technology to reconstruct historical mechanisms. Over the two years I’ve worked on this project, I’ve come to know the Kassel Hand model well. As we fine-tuned designs, I’ve created and edited its computer-aided design files – the digital 3D constructions of the model – and printed and assembled its parts countless times.

Examining parts midassembly is a crucial checkpoint for our prototypes. This quality control catches, corrects and prevents any defects, such as misprinted or damaged parts. It’s crucial for creating consistent and repeatable experiments. A new model version or component change never leaves the lab without passing rigorous inspection. This process means there are ways this model has behaved over time that the rest of the team has never seen. But I have.

So when I heard the release lever had broken in Birmingham, it was just another Thursday. While it had never snapped when we tested the model on people, I’d seen it break plenty of times while performing checks on components.

After all, the model is made from relatively weak polylactic acid. Perhaps the most difficult part of our work is making a plastic model as durable as possible while keeping it visually consistent with the 500-year-old original. The iron rod of the artifact’s lever can handle more force than our plastic version, at least five times the yield strength.

I suspected the lever had snapped because people pulled the trigger too far back and too quickly. The challenge, then, was to prevent this. But redesigning the lever to be thicker or a different shape would make it less like the historical artifact.

This raised the question: Why could I use the model without breaking the lever, but no one else could?

The team makes a plan

THE TEAM: A flurry of discussion led to growing consensus – the crux of the issue was not the model, it was the user.

The original Kassel Hand’s wearer would have learned to use their prosthesis through practice. Likewise, our team had learned to use the model over time. Through the process of design and development, prototyping and printing, we were inadvertently practicing how to operate it.

We needed to teach others to do the same. And this called for a two-pronged approach.

The engineers reexamined the opening through which the release trigger poked out of the model. They proposed shortening it to limit how far back users could pull it. When we checked how this change would affect the model’s accuracy, we found that a smaller opening was actually closer to the artifact’s dimensions. While the larger opening had been necessary for an earlier version of the release lever that needed to travel farther, now it only caused problems. The engineers got to work.

The historians, meanwhile, created plans to document and share the various techniques to operating the model the team hadn’t realized it had honed. To teach someone at home how to operate their own copy, we filmed a short video explaining how to lock and release the fingers and troubleshoot when a finger sticks.

Testing the plan

Exactly one week after what we called “the Birmingham Break,” we shared the model with a general audience again. This time we visited a colleague’s history class at Auburn.

We brought four copies. Each had an insert to shorten the opening around the trigger. First, we played our new instructional video on a projector. Then we turned the models over to the students to try.

The result? Not a single broken lever. We publicly launched the project on schedule.

The process of introducing the Kassel Hand model to the public highlights that just as the 16th-century amputee who wore the artifact had to learn to use it, one must learn to use the 3D-printed model, too.

It is a potent reminder that technology is not just a matter of mechanisms and design. It is fundamentally about people – and how people use it.

Heidi Hausse received funding from the Herzog August Bibliothek; the Consortium for History of Science, Technology and Medicine; the American Council of Learned Societies; the Huntington Library; the Society of Fellows in the Humanities at Columbia University; and the Renaissance Society of America.

Peden Jones received funding from Renaissance Society of America.

Read These Next

Failure of US-Iran talks was all-too predictable – but Trump could still have stuck with diplomacy o

Silence from the US side after a third round of indirect talks and frustration expressed by President…

Kansas revoked transgender people’s IDs overnight – researchers anticipate cascading health and soci

With invalid driver’s licenses and birth certificates, transgender people are at risk for more than…

Massive US attacks on Iran unlikely to produce regime change in Tehran

President Trump has appealed to Iranians to topple their government, but a popular uprising is unlikely…