To spur the construction of affordable, resilient homes, the future is concrete

When most Americans imagine a home, they picture a wood-framed house. But in an era of high housing costs and extreme weather events, precast concrete offers a mix of durability and efficiency.

Wood is, by far, the most common material used in the U.S. for single-family home construction.

But wood construction isn’t engineered for long-term durability, and it often underperforms, particularly in the face of increasingly common extreme weather events.

In response to these challenges, I believe mass-produced concrete homes can offer affordable, resilient housing in the U.S. By leveraging the latest innovations of the precast concrete industry, this type of homebuilding can meet the needs of a changing world.

Wood’s rise to power

Over 90% of the new homes built in the U.S. rely on wood framing.

Wood has deep historical roots as a building material in the U.S., dating back to the earliest European settlers who constructed shelters using the abundant native timber. One of the most recognizable typologies was the log cabin, built from large tree trunks notched at the corners for structural stability.

In the 1830s, wood construction underwent a significant shift with the introduction of balloon framing. This system used standardized, sawed lumber and mass-produced nails, allowing much smaller wood components to replace the earlier heavy timber frames. It could be assembled by unskilled labor using simple tools, making it both accessible and economical.

In the early 20th century, balloon framing evolved into platform framing, which became the dominant method. By using shorter lumber lengths, platform framing allowed each floor to be built as a separate working platform, simplifying construction and improving its efficiency.

The proliferation and evolution of wood construction helped shape the architectural and cultural identity of the nation. For centuries, wood-framed houses have defined the American idea of home – so much so that, even today, when Americans imagine a house, they typically envision one built of wood.

Today, light-frame wood construction dominates the U.S. residential market.

Wood is relatively affordable and readily available, offering a cost-effective solution for homebuilding. Contractors are familiar with wood construction techniques. In addition, building codes and regulations have long been tailored to wood-frame systems, further reinforcing their prevalence in the housing industry.

Despite its advantages, wood light-frame construction presents several important limitations. Wood is vulnerable to fire. And in hurricane- and tornado-prone regions, wood-framed homes can be damaged or destroyed.

Wood is also highly susceptible to water-related issues, such as swelling, warping and structural deterioration caused by leaks or flooding. Vulnerability to termites, mold, rot and mildew further compromise the longevity and safety of wood-framed structures, especially in humid or poorly ventilated environments.

The case for concrete

Meanwhile, concrete has revolutionized architecture and engineering over the past century. In my academic work, I’ve studied, written and taught about the material’s many advantages.

The material offers unmatched strength and durability, while also allowing design flexibility and versatility. It’s low-cost and low-maintenance, and it has high thermal mass properties, which refers to the material’s ability to absorb and store heat during the day, and slowly release it during the cooler nights. This can lower heating and cooling costs.

Properly designed concrete enclosures offer exceptional performance against a wide range of hazards. Concrete can withstand fire, flooding, mold, insect infestation, earthquakes, hail, hurricanes and tornadoes.

It’s commonly used for home construction in many parts of the world, such as Europe, Japan, Mexico, Brazil and Argentina, as well as India and other parts of Southeast Asia.

However, despite their multiple benefits, concrete single-family homes are rare in the U.S.

That’s because most concrete structures are built using a process called cast-in-place. In this technique, the concrete is formed and poured directly at the construction site. The method relies on built-in-place molds. After the concrete is cast and cured over several days, the formwork is removed.

This process is labor-intensive and time-consuming, and it often produces considerable waste. This is particularly an issue in the U.S., where labor is more expensive than in other parts of the world. The material and labor cost can be as high as 35% to 60% of the total construction cost.

Portland cement, the binding agent in concrete, requires significant energy to produce, resulting in considerable carbon dioxide emissions. However, this environmental cost is often offset by concrete’s durability and long service life.

Concrete’s design flexibility and structural integrity make it particularly effective for large-scale structures. So in the U.S., you’ll see it used for large commercial buildings, skyscrapers and most highways, bridges, dams and other critical infrastructure projects.

But when it comes to single-family homes, cast-in-place concrete poses challenges to contractors. There are the higher initial construction costs, along with a lack of subcontractor expertise. For these reasons, most builders and contractors stick with what they know: the wood frame.

A new model for home construction

Precast concrete, however, offers a promising alternative.

Unlike cast-in-place concrete, precast systems allow for off-site manufacturing under controlled conditions. This improves the quality of the structure, while also reducing waste and labor.

The CRETE House, a prototype I worked on in 2017 alongside a team at Washington University in St. Louis, showed the advantages of a precast home construction.

To build the precast concrete home, we used ultra-high-performance concrete, one of the latest advances in the concrete industry. Compared with conventional concrete, it’s about six times stronger, virtually impermeable and more resistant to freeze-thaw cycles. Ultra-high-performance concrete can last several hundred years.

The strength of the CRETE House was tested by shooting a piece of wood at 120 mph (193 kph) to simulate flying debris from an F5 tornado. It was unable to breach the wall, which was only 2 inches (5.1 centimeters) thick.

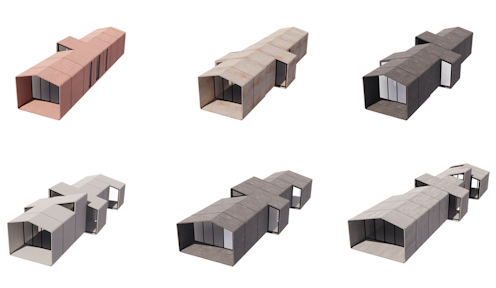

Building on the success of the CRETE House, I designed the Compact House as a solution for affordable, resilient housing. The house consists of a modular, precast concrete system of “rings” that can be connected to form the entire structure – floors, walls and roofs – creating airtight, energy-efficient homes. A series of different rings can be chosen from a catalog to deliver different models that can range in size from 270 to 990 square feet (25 to 84 square meters).

The precast rings can be transported on flatbed trailers and assembled into a unit in a single day, drastically reducing on-site labor, time and cost.

Since they’re built using durable concrete forms, the house can be easily mass-produced. When precast concrete homes are mass-produced, the cost can be competitive with traditional wood-framed homes. Furthermore, the homes are designed to last far beyond 100 years – much longer than typical wood structures – while significantly lowering utility bills, maintenance expenses and insurance premiums.

The project is also envisioned as an open-source design. This means that the molds – which are expensive – are available for any precast producer to use and modify.

Leveraging a network that’s already in place

Two key limitations of precast concrete construction are the size and weight of the components and the distance to the project site.

Precast elements must comply with standard transportation regulations, which impose restrictions on both size and weight in order to pass under bridges and prevent road damage. As a result, components are typically limited to dimensions that can be safely and legally transported by truck. Each of the Compact House’s pieces are small enough to be transported in standard trailers.

Additionally, transportation costs become a major factor beyond a certain range. In general, the practical delivery radius from a precast plant to a construction site is 500 miles (805 kilometers). Anything beyond that becomes economically unfeasible.

However, the infrastructure to build precast concrete homes is already largely in place. Since precast concrete is often used for office buildings, schools, parking complexes and large apartments buildings, there’s already an extensive national network of manufacturing plants capable of producing and delivering components within that 500-mile radius.

There are other approaches to build homes with concrete: Homes can use concrete masonry units, which are similar to cinder blocks. This is a common technique around the world. Insulated concrete forms involve rigid foam blocks that are stacked like Lego bricks and are then filled with poured concrete, creating a structure with built-in insulation. And there’s even 3D-printed concrete, a rapidly evolving technology that is in its early stages of development.

However, none of these use precast concrete modules – the rings in my prototypes – and therefore require substantially longer on-site time and labor.

To me, precast concrete homes offer a compelling vision for the future of affordable housing. They signal a generational shift away from short-term construction and toward long-term value – redefining what it means to build for resilience, efficiency and equity in housing.

This article is part of a series centered on envisioning ways to deal with the housing crisis.

Pablo Moyano Fernández does not work for, consult, own shares in or receive funding from any company or organization that would benefit from this article, and has disclosed no relevant affiliations beyond their academic appointment.

Read These Next

China’s muted response over war in Iran reflects Beijing’s delicate calculus as a concerned onlooker

Beijing has denounced US-Israeli action in Iran, but has not rushed to come to the aid of its regional…

Venezuela’s fragile forests face rising risks as US pushes for oil and critical minerals and illegal

The Orinoco Basin is one of the most biodiverse places on the planet. It’s also rich in oil, gold…

Measuring poverty on a spectrum instead of an arbitrary line conveys a more accurate picture of ineq

An economist proposes a new method of estimating the scope of poverty in different countries.